Quiet Power: Why Linear Actuators Are a Key Element of Modern Automation

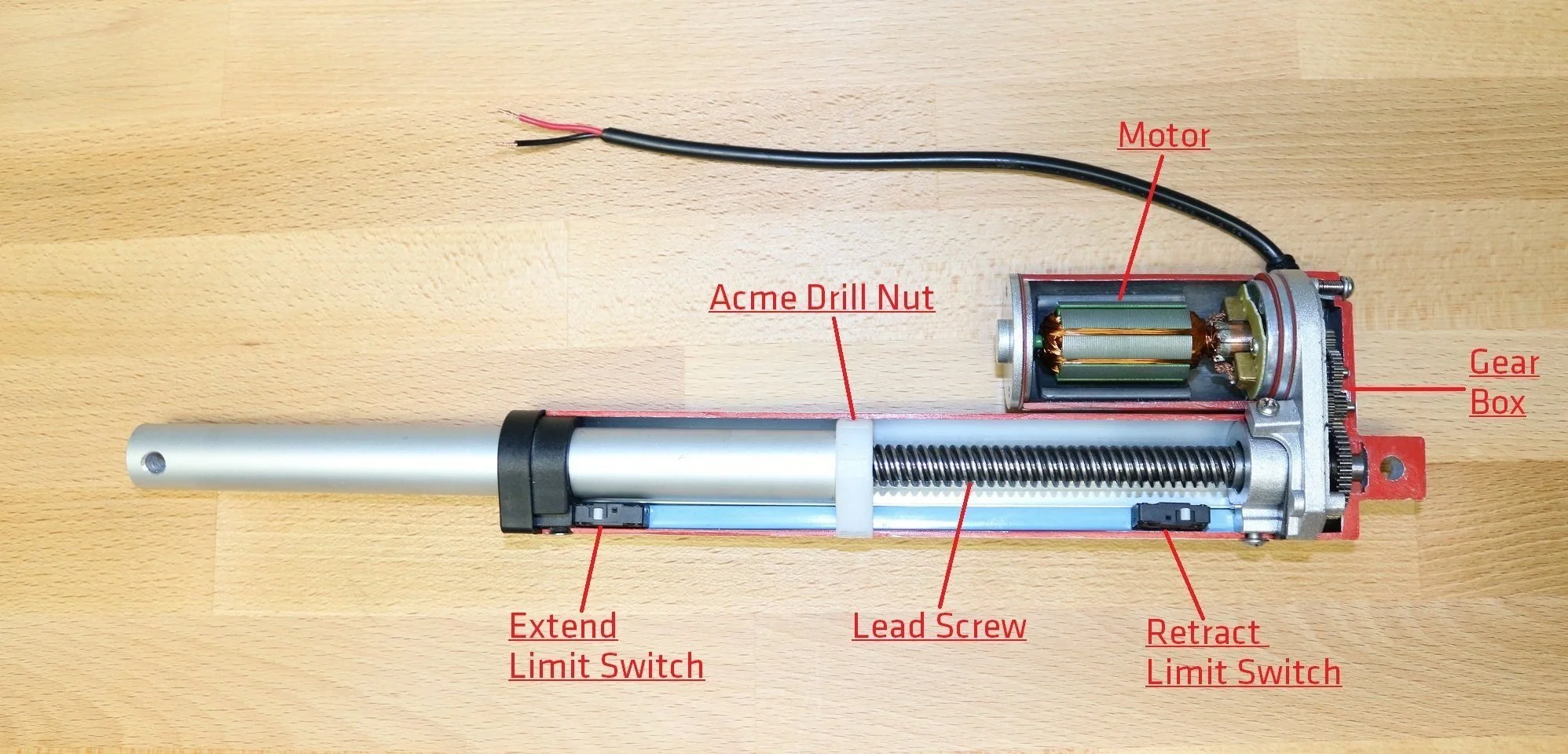

Linear actuators are compact, reliable devices that create straight-line motion and serve numerous applications ranging from industrial machinery to medical equipment to smart home systems. Actuators transform energy, electrical, hydraulic, or pneumatic, into linear motion, unlike conventional rotating motors. Through an actuator, users move the motion along a straight line, which differs from traditional turning motors, resulting in fewer losses and increasing system operability.

This enables higher accuracy and stability in operation. Linear actuators include several types, including electromechanical, hydraulic, pneumatic, piezoelectric, and magnetic. Each of these types is most appropriate for a given state and job. Choose an actuator based on force, speed, duty cycle, integration, operating conditions, power, and maintenance. The application to which these actuators have a scope is very wide as well; they are being put to work in CNC machinery for accurate tool steering, in robotics, in automotive control systems, and in a number of medical devices.

Consistent care and maintenance keep them running and serve as life-long systems. Linear actuators are the basic elements of modern technology across the board; they provide the accuracy, convenience, and reliability of many systems, which further makes them an essential component of the technology.

General Features of Linear Actuators That Contribute to Their Demand for Automation

We have many different types of linear actuators that have different operating principles and are used differently from each other, including screw actuators, hydrodynamic actuators, pneumatic actuators, electric actuators, etc. The features and benefits of these products consist of the following:

Resistance devices: When it comes to equipment used for high-speed, high-frequency, or low-frequency purposes, the best performer on the market is your typical actuator.

Movement: Linear actuators move linearly throughout a wide range. That means they can perform a few millimeters to several meters of linear movement with precision.

Maximum load: They can withstand heavy loads, making them suitable for heavy-load applications in industry and automation.

Speed and accuracy: Linear actuators provide high-speed movement and high positioning accuracy.

Control: They can be easily incorporated into control systems such as electronic automation or remote control systems. Linear actuators are used in various industries, including the automotive industry, medical devices, furniture manufacturing, automated production systems, solar panels, robotics, and many other areas.

Energy saving: Some linear actuators work on systems with low power consumption, hence they are designed to avoid energy loss and have stable, consistent performance.

They are now basic elements in most new technologies and automation systems. They offer high efficiency, reliability, and absolute accuracy in linear control of motion and are employed in many areas and processes related to production.

Quiet Power in Action: Real-World Applications

One reason linear actuators are now a foundational part of most modern automation is how smoothly and silently they work. In many systems, noise is a functional issue and a source of annoyance. For example, in medical equipment like hospital beds, dental chairs, or imaging devices, loud motors can increase stress for patients and make precise adjustments harder for clinicians. Electric linear actuators, particularly those with integrated gearboxes and high-quality bearings, also provide powerful motion while keeping the noise levels exceptionally low, sometimes below 45 dB. That’s quieter than a normal conversation.

Another area where actuators make a surprisingly big impact is agriculture. Farming now uses technology such as automated feeding systems, greenhouse ventilation, and seed-sorting equipment. Linear actuators open and close heavy panels, adjust conveyor angles, and regulate airflow. Fun fact: In advanced greenhouses, temperature and humidity changes trigger dozens of tiny actuators every hour to optimize plant conditions, acting almost like a “nervous system” for the building.

Precision That Feels Effortless

The key benefit of linear actuators is that they move precisely where they’re instructed to move – no drift, no wobble, no correction required afterward. Which is why they’re now standard in CNC machines, 3D printers, laser cutters, and automated measuring systems.

The accuracy at the level of microns is achievable with some types of actuators, especially ball-screw type and piezoelectric type of actuators. These precision measures in optical and photoelectric design are vital for maintaining the level of accuracy. Professional camera sliders and gimbal stabilizers are built of compact actuators to control steady, precise operation. That is why you can enjoy a product video or nature clip filmed in perfect slow motion without realizing that even a small actuator is doing all the legwork behind the scenes.

Linear Actuators and Smart Living

Smart homes are rapidly becoming part of the mainstream, and actuators subtly underwrite many of the features people now consider routine. Adjustable standing desks? Actuators. TVs hidden from cabinets that stand out? Actuators. Automatic windows that close during rain, beds that adapt to your sleep position, kitchen cabinets that automatically lift if you simply press a button - all via compact electric actuators. A trend of particular note is smart furniture prioritizing accessibility. For folks with limited mobility, actuators are helping create adaptive home environments, from height-adjustable countertops to motorized recliners. Powered by sensors, software and actuators, these systems assemble furniture that “responds” in this way to the user in real time, enhancing independence and comfort.

See How Power and Smooth Control Come Together

Linear actuators are great for consumer and medical products, and equally useful in heavy-duty settings. Industrial-grade actuators move hundreds, even thousands, of pounds with constant force and precise speed input. For instance:

They are used in mining equipment to control chute gates and heavy ventilation systems. For aerospace ground systems, actuators help to mold and angle wings during assembly or perform calibration tests. Hydraulic actuators are used in construction machines for lifting and stabilizing structures in the construction sector. However, despite all that force, contemporary actuators in large machinery are generally tuned to be noise and vibration minimized. The quiet performance improves safety in the workplace, communication, and technician comfort.

Linear Actuators and Energy Efficiency

The next reason linear actuators are being increasingly used in practice now is that they minimize waste. Electric actuators, particularly, draw power only when they drive. Once they’ve arrived at a stable position, they can remain there and can consume virtually no energy, a significant contrast to hydraulic systems, which often have to be kept under constant pressure. This feature is the key to making them suited for solar tracking systems.

Energy production is increased by 25 to 35 percent in the course of a day by using actuators that tilt solar panels toward the sun during the day, depending on the climate. Each actuator only works for a few seconds an hour, so the system runs smoothly, with little maintenance.

Actuators, Their Rise in Autonomous Machines

With a high reliance on actuators, robots and autonomous machines closely imitate human behavior. Whether it’s a robot arm positioning microchips or a mobile robot repositioning its suspension over rough ground, actuators are the “muscles” of the system. In collaborative robots (cobots), machines programmed to coexist without dangers, quiet, smooth, and predictable motion is important. Linear actuators enable these robots to engage in gentle interactions such as holding items for others to stick, putting down adhesive, or completing assembly jobs without jerking around. One interesting instance here is robotic exoskeletons.

These wearables allow people with mobility challenges to walk again or aid workers in reducing strain during heavy lifting. Linear actuators designed inside exoskeletons need to be compact, powerful, responsive, and safe – a hybrid approach, for example. Silent Power will pave the Road of Automation. More and more companies are looking for cleaner, more efficient, and more accurate automation, and linear actuators continue to advance. Already today, we observe trends as follows:

Intelligent actuators with sensors and self-diagnosis. Remote adjustments with wireless controls. Built-in safety features to prevent accidental overloading

Environmentally friendly materials and better durability coatings. Miniaturization to make actuators smaller yet more impactful. Smarter motion systems could even include future-proof predictive adjustment systems, adaptive control systems with real-time load adaptability, and systems that can seamlessly leverage AI-driven control features. What is constant, though, is the function of the actuators themselves: transmitting motion, quietly and accurately but regularly.

Today, modern automation would not be similar without them. As more technologies are geared toward adaptive, intelligent, and human-friendly systems, the significance of linear actuators will only increase.